Address

B-61, GIDC, Electronics Estate, Sector 25, Gandhinagar-382028, Gujarat, India.

Email

info.chetumaxsales@gmail.com

Mobile

+91 8490802084

+91 9327083092

Work Hours

Monday to Friday: 9 AM - 7 PM

Address

B-61, GIDC, Electronics Estate, Sector 25, Gandhinagar-382028, Gujarat, India.

Email

info.chetumaxsales@gmail.com

Mobile

+91 8490802084

+91 9327083092

Work Hours

Monday to Friday: 9 AM - 7 PM

Sections / Key Points:

1.What is CCL and why it’s the base of PCB performance

A Copper Clad Laminate (CCL) is a basic material used to make printed circuit boards (PCBs), consisting of a thin sheet of copper foil bonded to an insulating core, like a fiberglass-reinforced epoxy resin. These laminates provide the necessary electrical insulation and mechanical support for circuits, and are processed to create the conductive pathways on a PCB.

2.Types of CCL Materials / Substrates

3.Key Properties to Consider

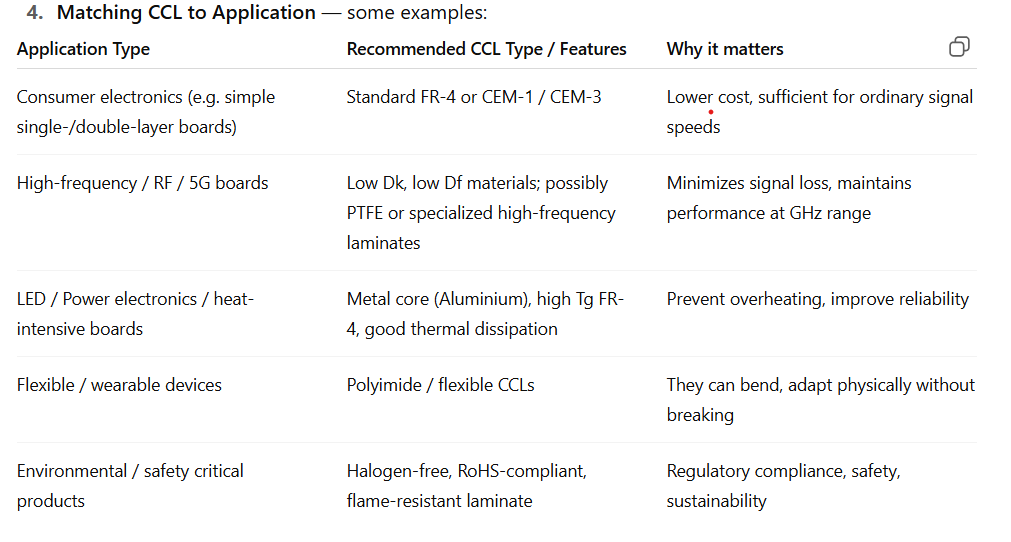

4.Cost vs Performance Trade-Offs

How Chetumax Sales and MM Enterprise assist you in choosing according to your needs:

Design and Output

From File to Film

Printing the Inner layers

Removing the Unwanted Copper

Layer Alignment and Optical Inspection

Layer-up and Bond

PCB Drill

Plating and Copper Deposition

Outer Layer Imaging

Plating

Final Etching

Solder Mask Application

Surface Finish

Silkscreen

Electrical Test

Profiling and V-Scoring